Spherical Shell Calculator

Calculator and formulas for calculating a spherical shell

Spherical Shell Calculator

The Spherical Shell

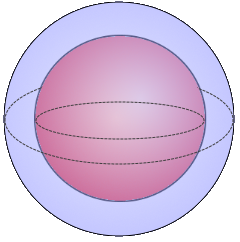

The spherical shell (also called hollow sphere) is created by a spherical cavity in a larger sphere.

Spherical Shell Properties

The spherical shell: Hollow space with constant wall thickness

Spherical Shell Visualization

The Spherical Shell

Hollow sphere with constant wall thickness

Optimal material distribution for hollow spheres.

Light but stable.

|

|

What is a spherical shell?

The spherical shell is a special geometric shape:

- Definition: Hollow sphere with spherical cavity inside

- Structure: Large sphere minus smaller concentric sphere

- Wall thickness: Constant thickness a = R - r

- Material efficiency: Maximum stability with minimal material

- Application: Pressure vessels, ball bearings, architecture

- Feature: Double surface calculation (inside + outside)

Geometric properties of the spherical shell

The spherical shell shows unique geometric properties:

Basic parameters

- Outer radius R: Radius of the outer sphere surface

- Inner radius r: Radius of the spherical cavity

- Shell thickness a: Wall thickness a = R - r

- Concentricity: Both spheres have the same center

Special properties

- Double surface: Outer plus inner surface

- Material efficiency: Optimal stability/weight ratio

- Scalability: From thin shell to thick wall

- Symmetry: Complete spherical symmetry

Mathematical relationships of the spherical shell

The spherical shell follows elegant mathematical laws:

Volume formula

The shell volume as difference of two spheres. Elegant cubic difference formula.

Surface area formula

The total surface as sum of both sphere surfaces. Inner plus outer surface.

Applications of the spherical shell

Spherical shells find applications in various fields:

Mechanical Engineering & Technology

- Pressure vessels and tanks

- Ball bearings (hollow spheres)

- Lightweight constructions

- Precision mechanics

Aerospace & Aviation

- Satellite tanks

- Pressure cabins

- Lightweight structures

- Fuel tanks

Architecture & Construction

- Dome constructions

- Modern architecture

- Sculptural elements

- Lightweight roofs

Science & Research

- High-pressure experiments

- Materials research

- Physical models

- Biomechanics

Formulas for the spherical shell

Shell Thickness (a)

Difference between outer and inner radius

Shell Volume (V)

Difference of sphere volumes

Surface Area (S)

Sum of outer and inner surfaces

Individual Surfaces

Outer and inner surfaces separately

Geometric relationships

\(R > r > 0\)

\(a = R - r\)

Optimal with thin walls

The outer radius must be larger than the inner radius

Calculation example for a spherical shell

Given

Find: All parameters of the spherical shell

1. Shell thickness calculation

For R = 10 cm, r = 7 cm:

\[a = R - r = 10 - 7\] \[a = 3 \text{ cm}\]The shell thickness is 3 cm

2. Volume calculation

With R = 10 cm, r = 7 cm:

\[V = \frac{4π}{3} \cdot (R^3 - r^3)\] \[V = \frac{4π}{3} \cdot (1000 - 343)\] \[V = \frac{4π}{3} \cdot 657 ≈ 2753.8 \text{ cm}^3\]The shell volume is approximately 2753.8 cm³

3. Surface area calculation

With R = 10 cm, r = 7 cm:

\[S = 4π \cdot (R^2 + r^2)\] \[S = 4π \cdot (100 + 49)\] \[S = 4π \cdot 149 ≈ 1870.8 \text{ cm}^2\]The total surface area is approximately 1870.8 cm²

4. Individual surfaces

Split by inner/outer:

\[S_{outer} = 4π \cdot 10^2 = 400π ≈ 1256.6 \text{ cm}^2\] \[S_{inner} = 4π \cdot 7^2 = 196π ≈ 615.8 \text{ cm}^2\]Outer surface: 1256.6 cm², Inner surface: 615.8 cm²

5. Summary

The spherical shell with 3 cm wall thickness

6. Comparison with solid sphere

V = 2753.8 cm³

V = 4188.8 cm³

The hollow sphere saves about 1/3 material

7. Material efficiency analysis

a/R = 3/10 = 0.3

r³/R³ = 34.3%

Medium wall thickness

Very good balance

Optimal balance between stability and material savings

The Spherical Shell: Material efficiency through geometry

The spherical shell is a fascinating geometric shape that combines the elegance of sphere geometry with the principles of material efficiency. As a hollow sphere with constant wall thickness, it shows how maximum stability can be achieved with minimal material use through clever geometric design. The mathematical beauty lies in the elegant difference formulas for volume (R³-r³) and sum formulas for surfaces (R²+r²), which perfectly describe the essence of the hollow sphere.

The geometry of efficiency

The spherical shell shows the perfection of material-saving geometry:

- Double surface: Inner and outer surfaces for maximum functionality

- Constant wall thickness: Uniform material distribution and stability

- Spherical symmetry: Optimal pressure distribution in all directions

- Material efficiency: Maximum stability with minimal weight

- Scalability: From thin shells to thick walls

- Elegant mathematics: Simple difference and sum formulas

- Universal application: From microtechnology to large containers

Mathematical elegance

Difference formulas

The volume formula V = 4π/3 × (R³-r³) shows the elegant cubic difference that mathematically captures the essence of the hollow sphere.

Sum formulas

The surface formula S = 4π × (R²+r²) elegantly adds inner and outer surfaces to a total surface area.

Material optimization

The spherical shell enables material savings of 20-80% compared to solid spheres while maintaining structural integrity.

Technical perfection

In pressure vessels, spherical tanks and lightweight construction, the spherical shell shows its technical superiority through optimal stress distribution.

Summary

The spherical shell embodies the perfect harmony between geometric elegance and technical efficiency. As a hollow sphere with constant wall thickness, it unites the natural perfection of the spherical form with the principles of intelligent material utilization. Its mathematical properties - with the elegant difference formulas for volume and sum formulas for surface area - make it a fundamental building block of modern engineering. From high-pressure vessels to aerospace tanks to architectural dome constructions, the spherical shell shows its universal applicability. It impressively demonstrates how geometric perfection and practical material efficiency lead to technical solutions that are both mathematically beautiful and engineering optimal.

|

|

|

|